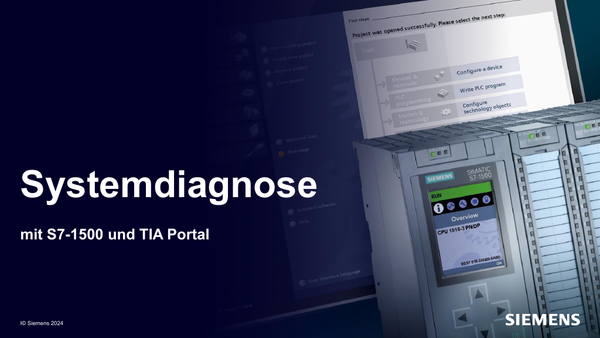

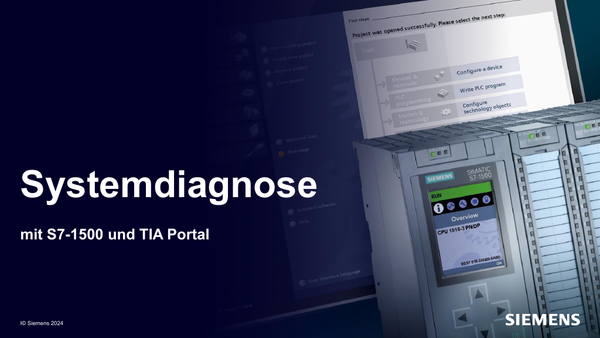

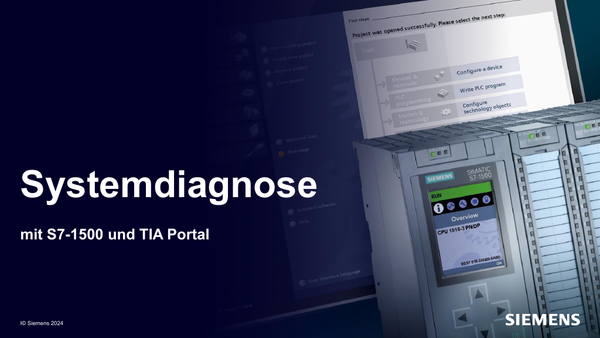

Overall Information

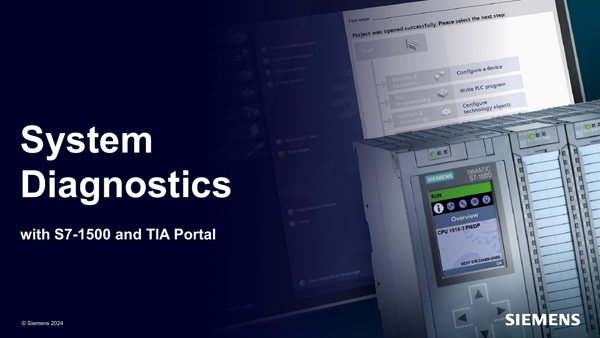

Get more insights in the topic of standardization of system and machine diagnostics.

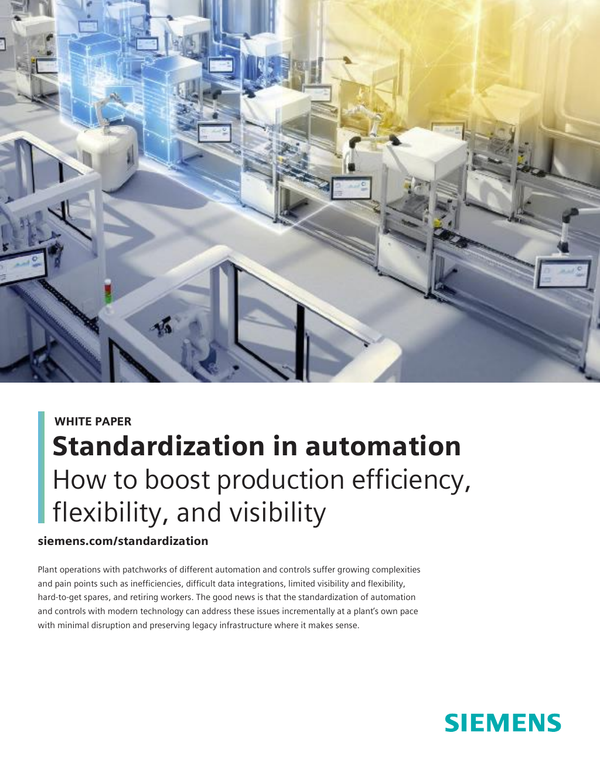

Without standardization, the search for the causes of a machine's failures or errors can take a long time. Specialists are often required for this. With a standardized diagnostic concept, you can display the condition of every machine on your screen and evaluate them quickly. That means you can quickly respond and reduce your downtimes.

Overall Information

Get more insights in the topic of standardization of system and machine diagnostics.

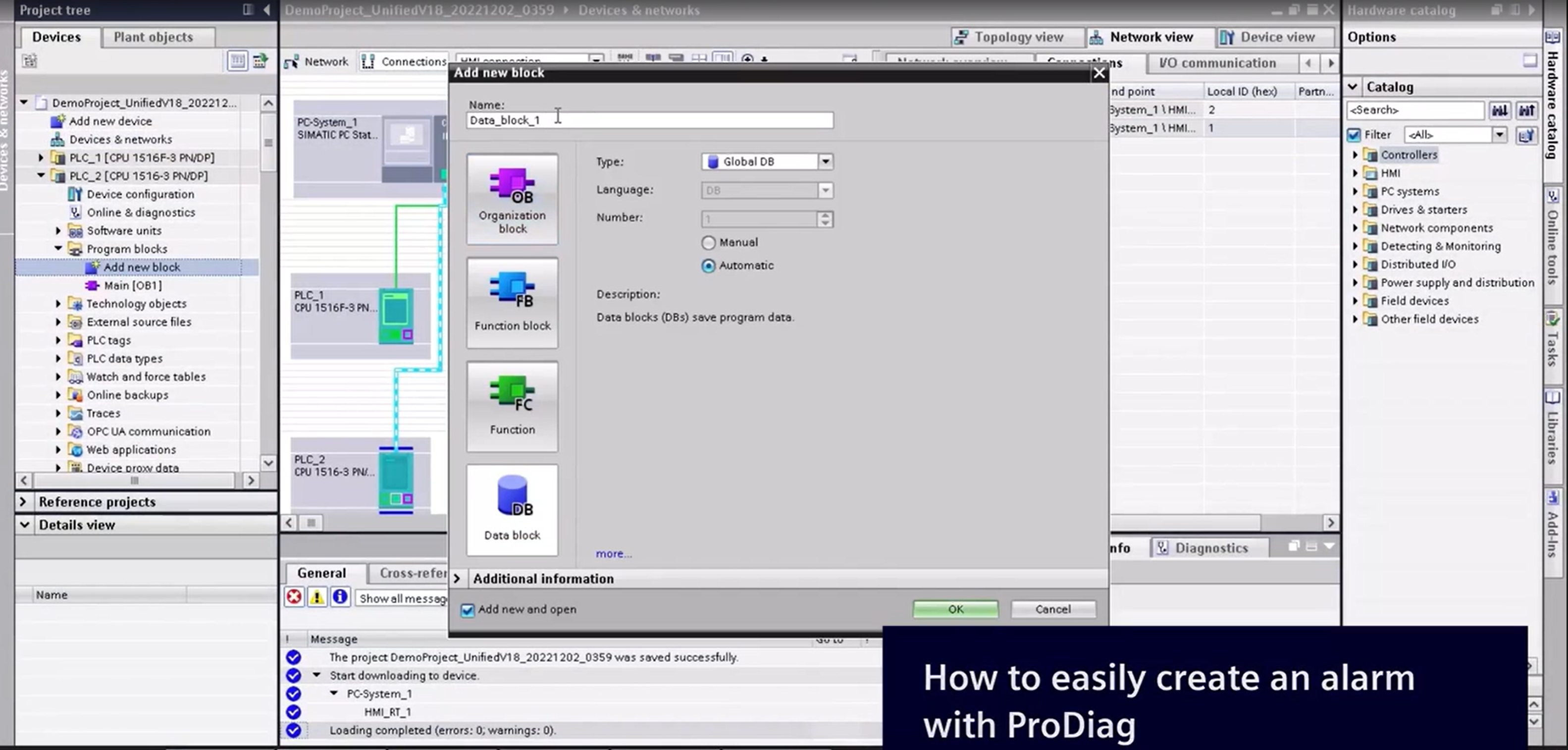

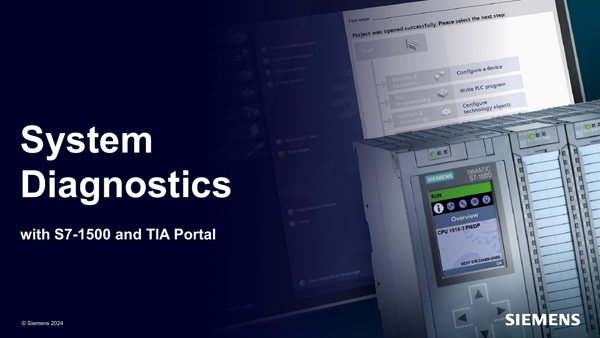

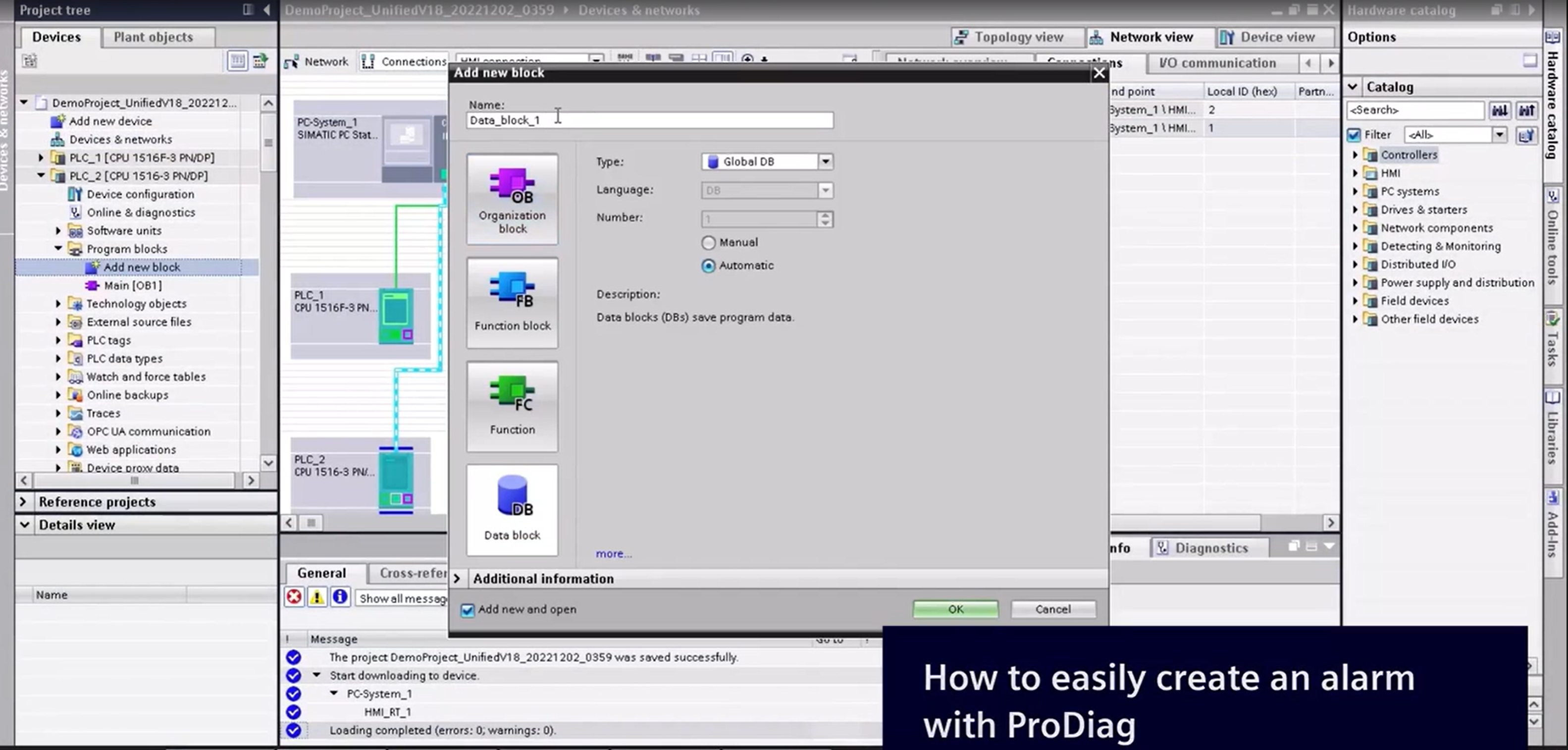

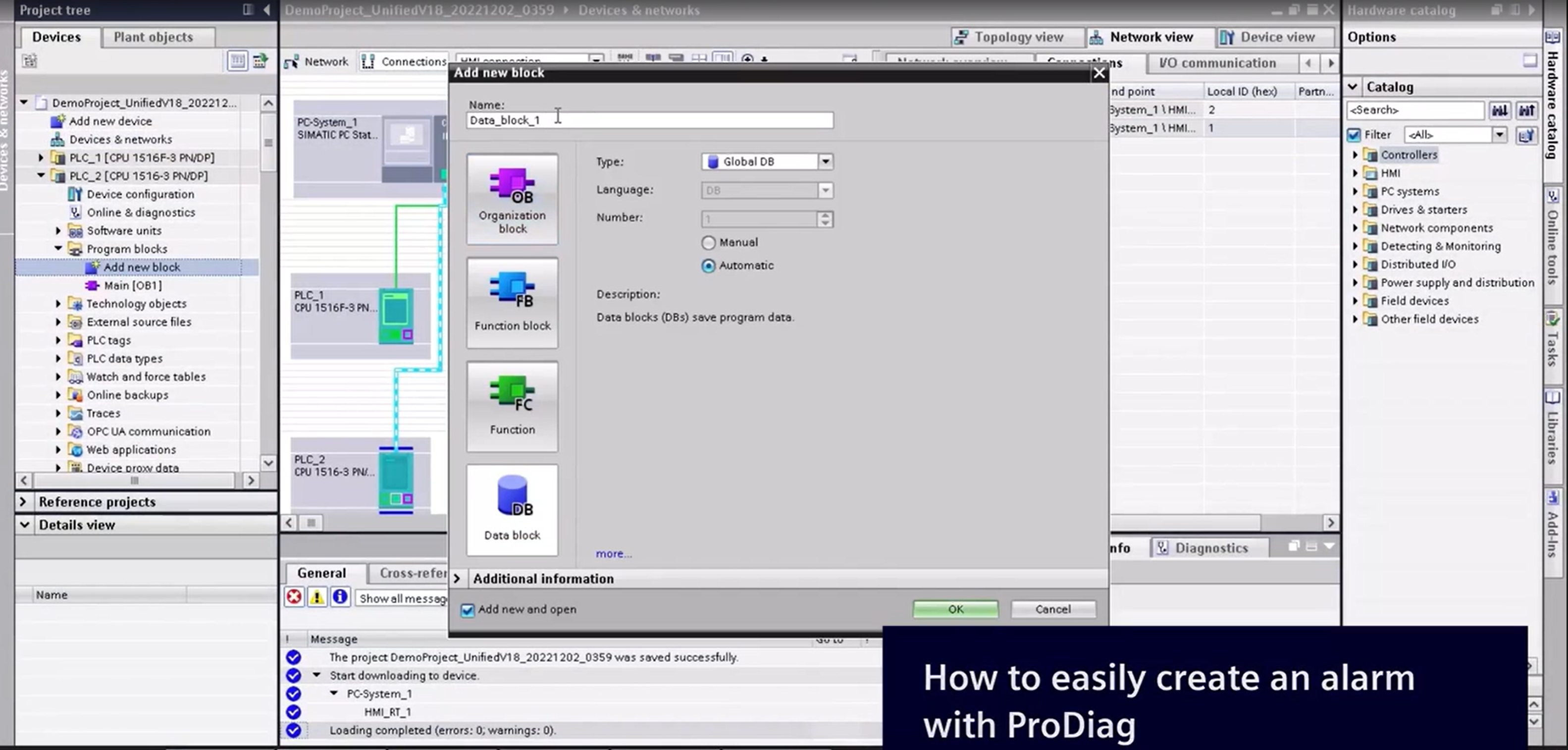

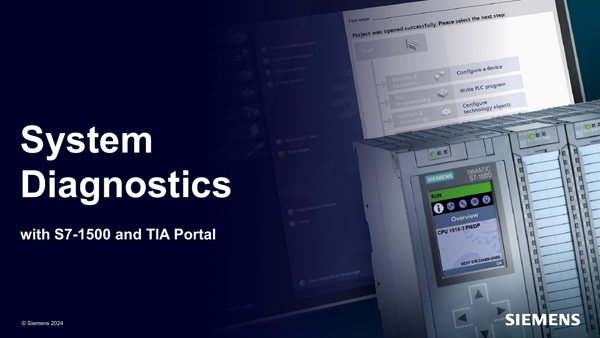

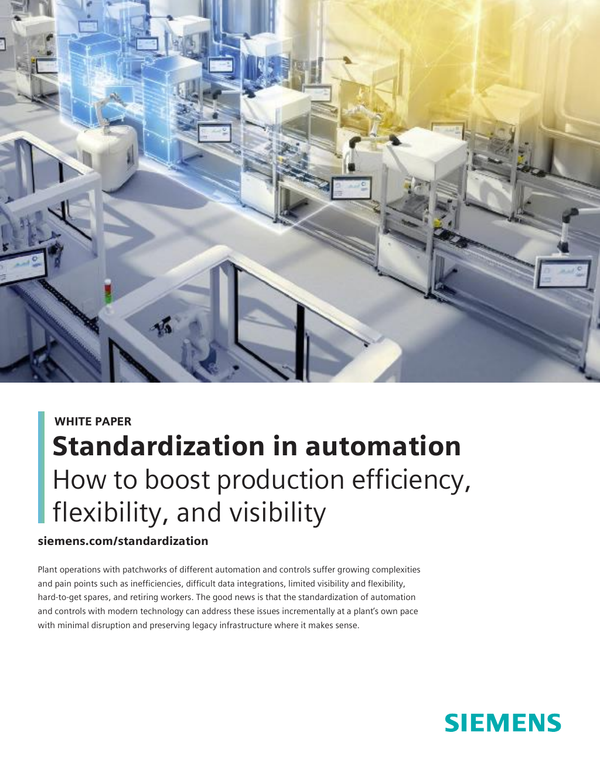

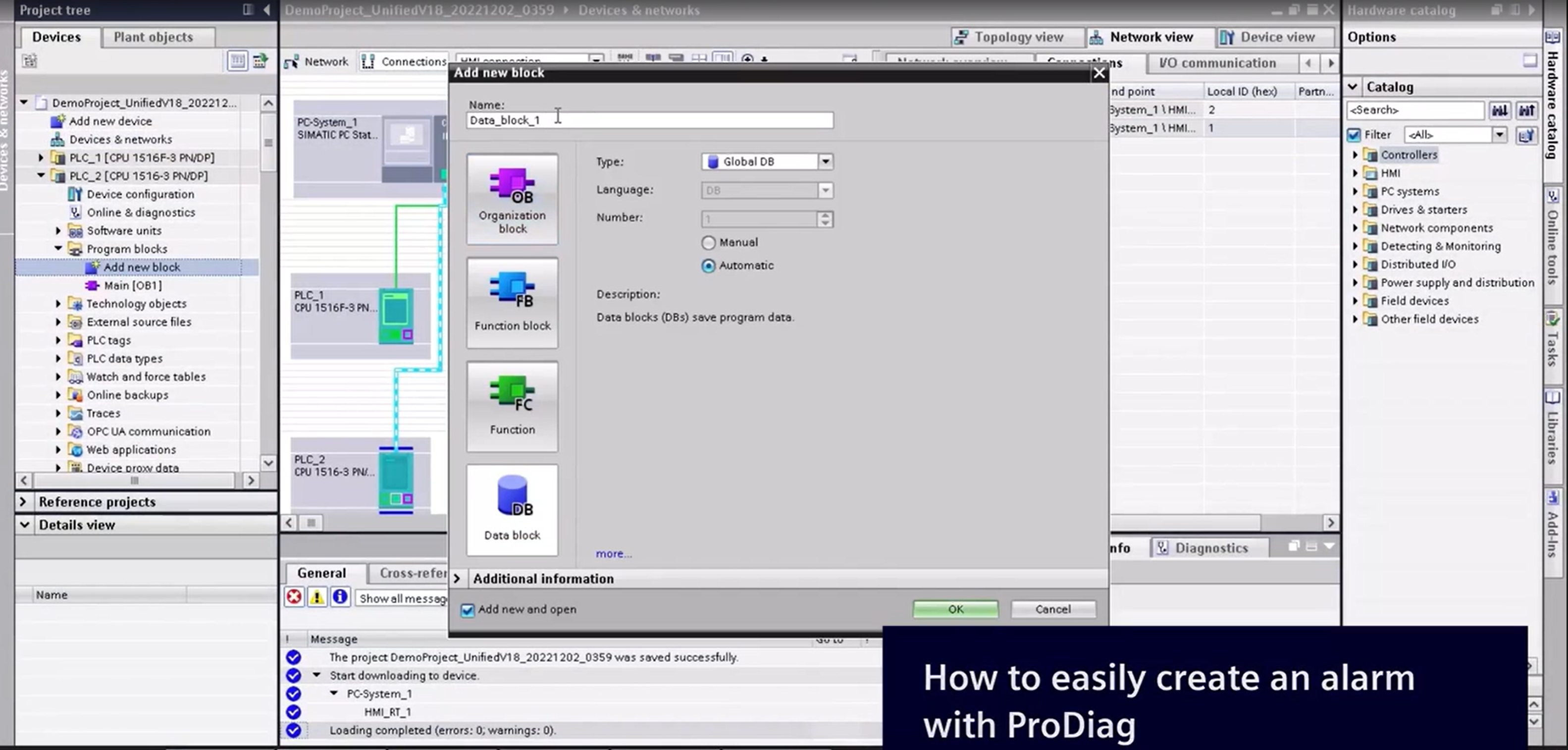

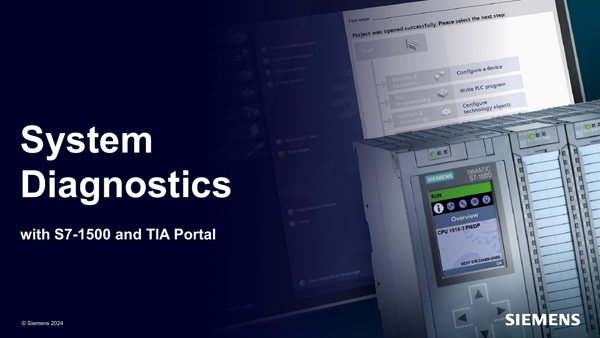

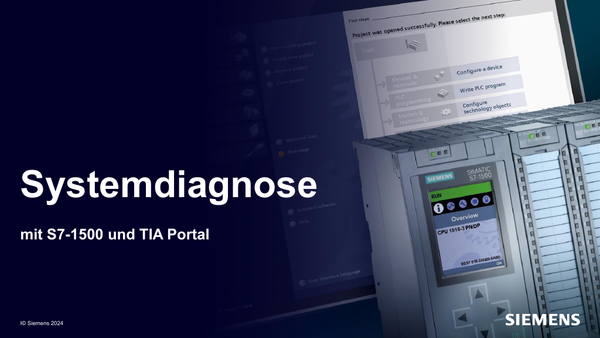

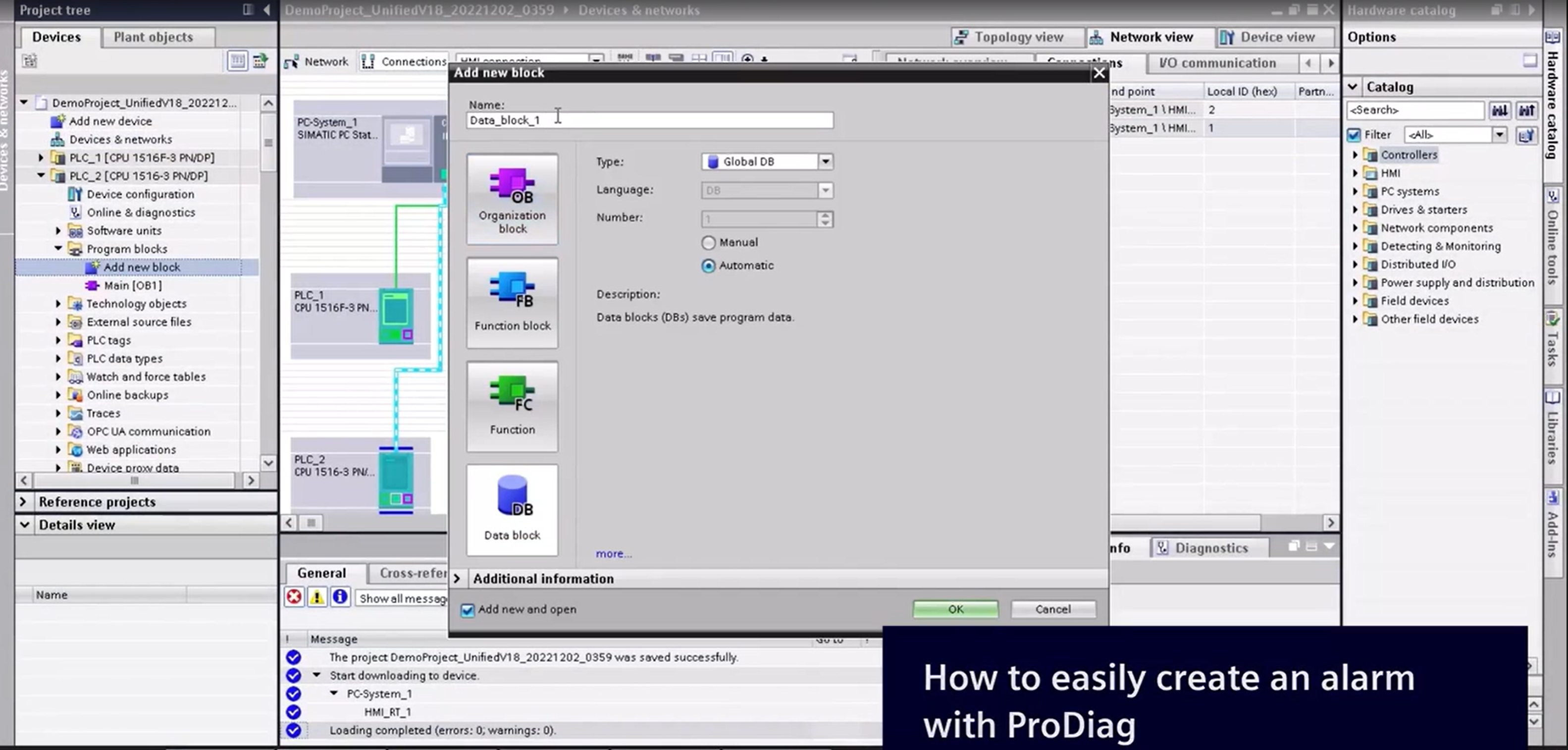

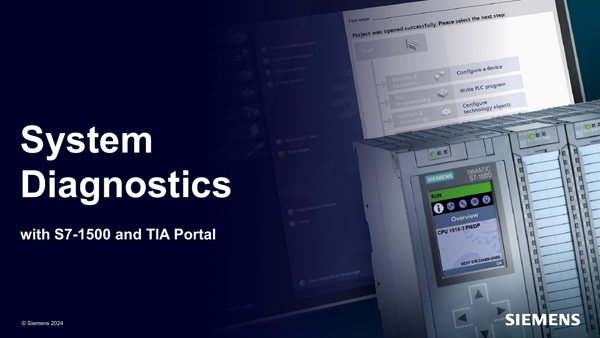

Standardize by configuration instead of programming

Siemens relies on a “configuration instead of programming” approach to harmonize diagnostic messages in order to make diagnostics and monitoring easier, quicker and more efficient.

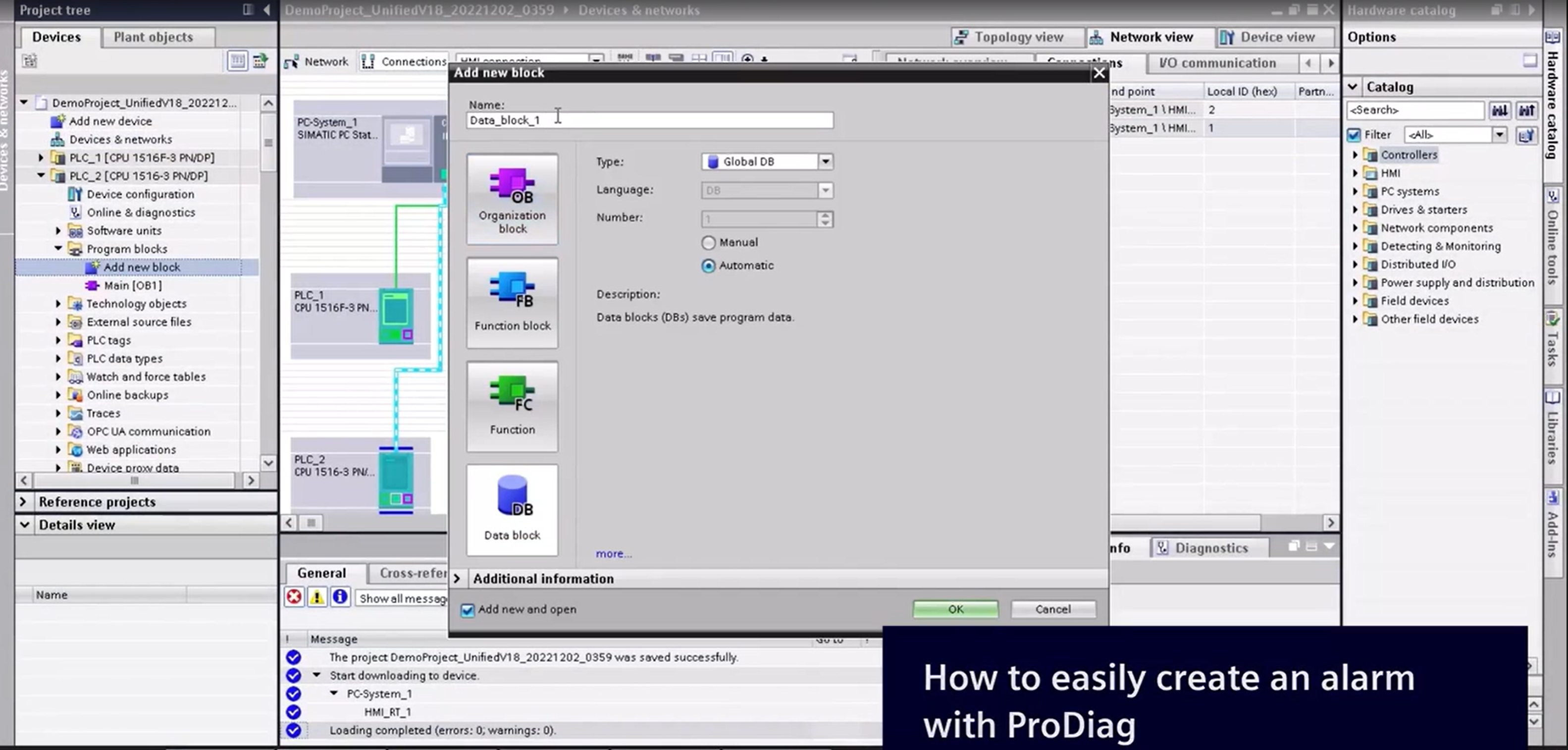

Complete System Integration

Thanks to the open communication standard OPC UA and its Alarms & Conditions specification, all diagnostic information from machines and systems with an SIMATIC S7-1200/1500 controller can be used by devices and systems from other manufacturers, regardless of the level of the automation pyramid.

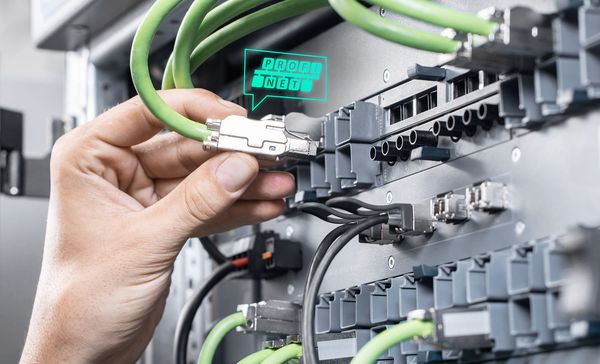

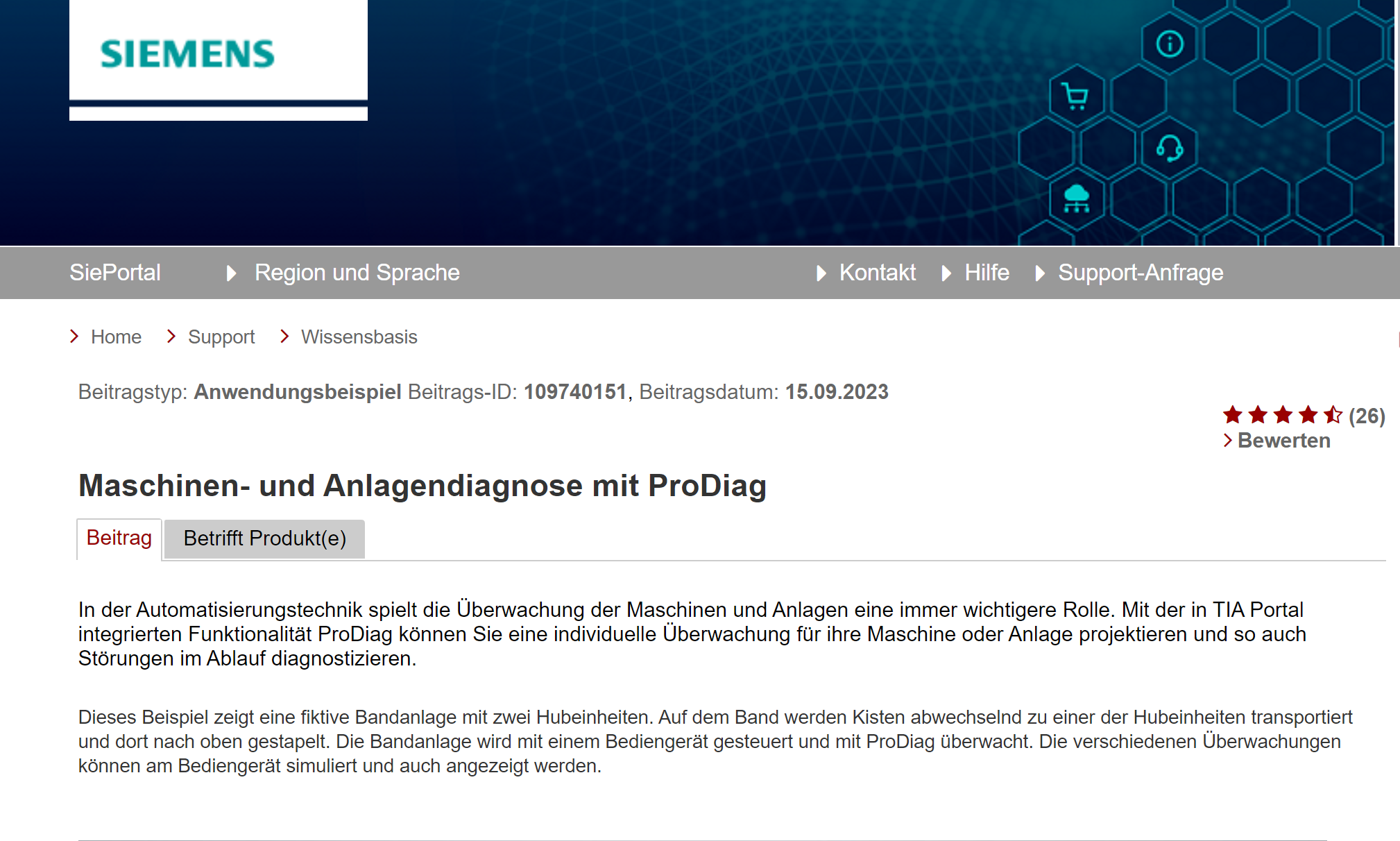

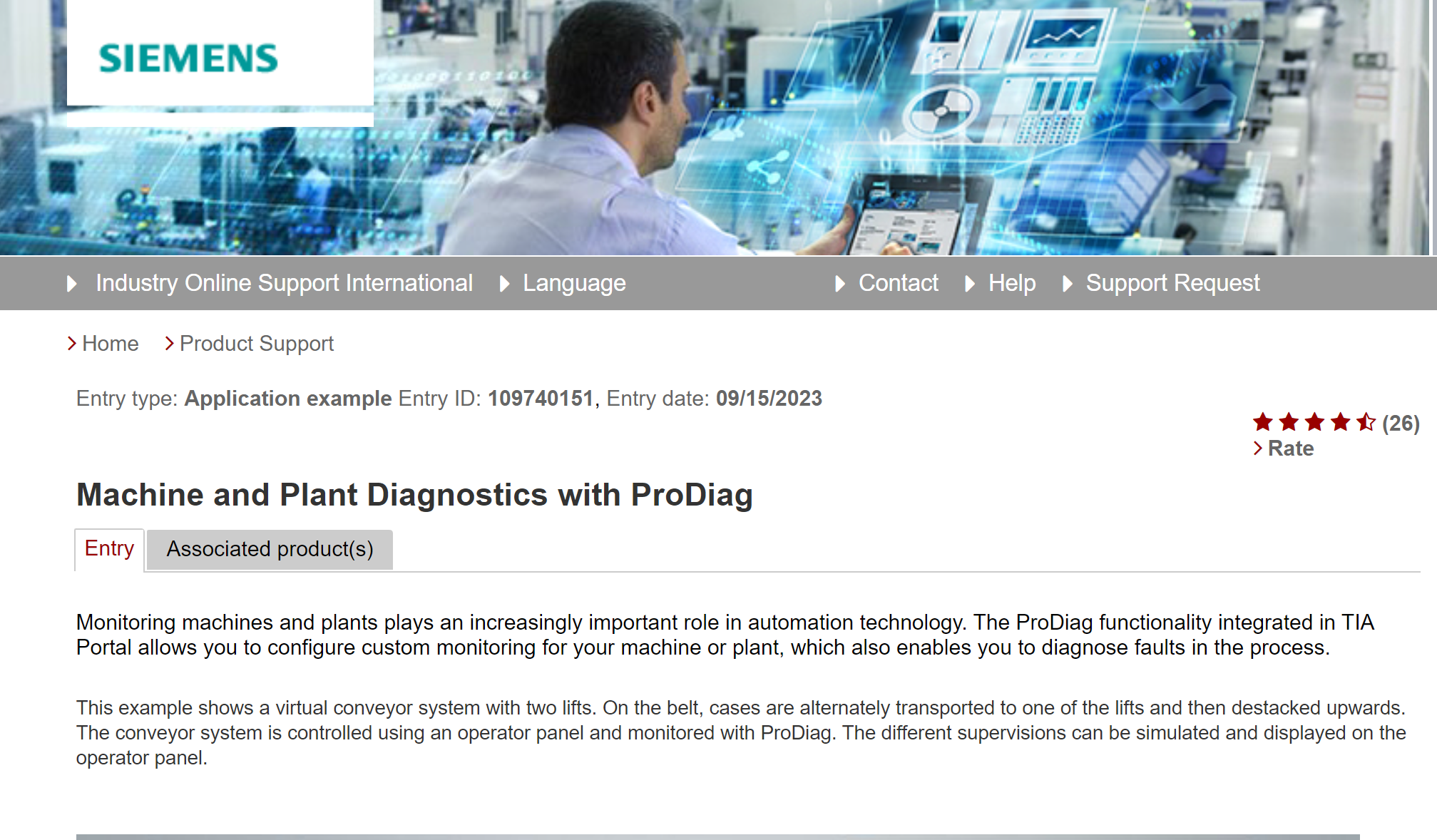

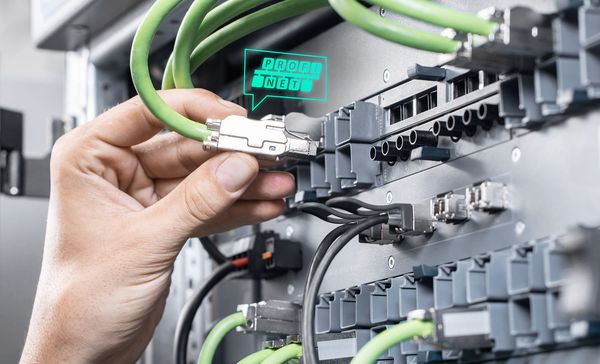

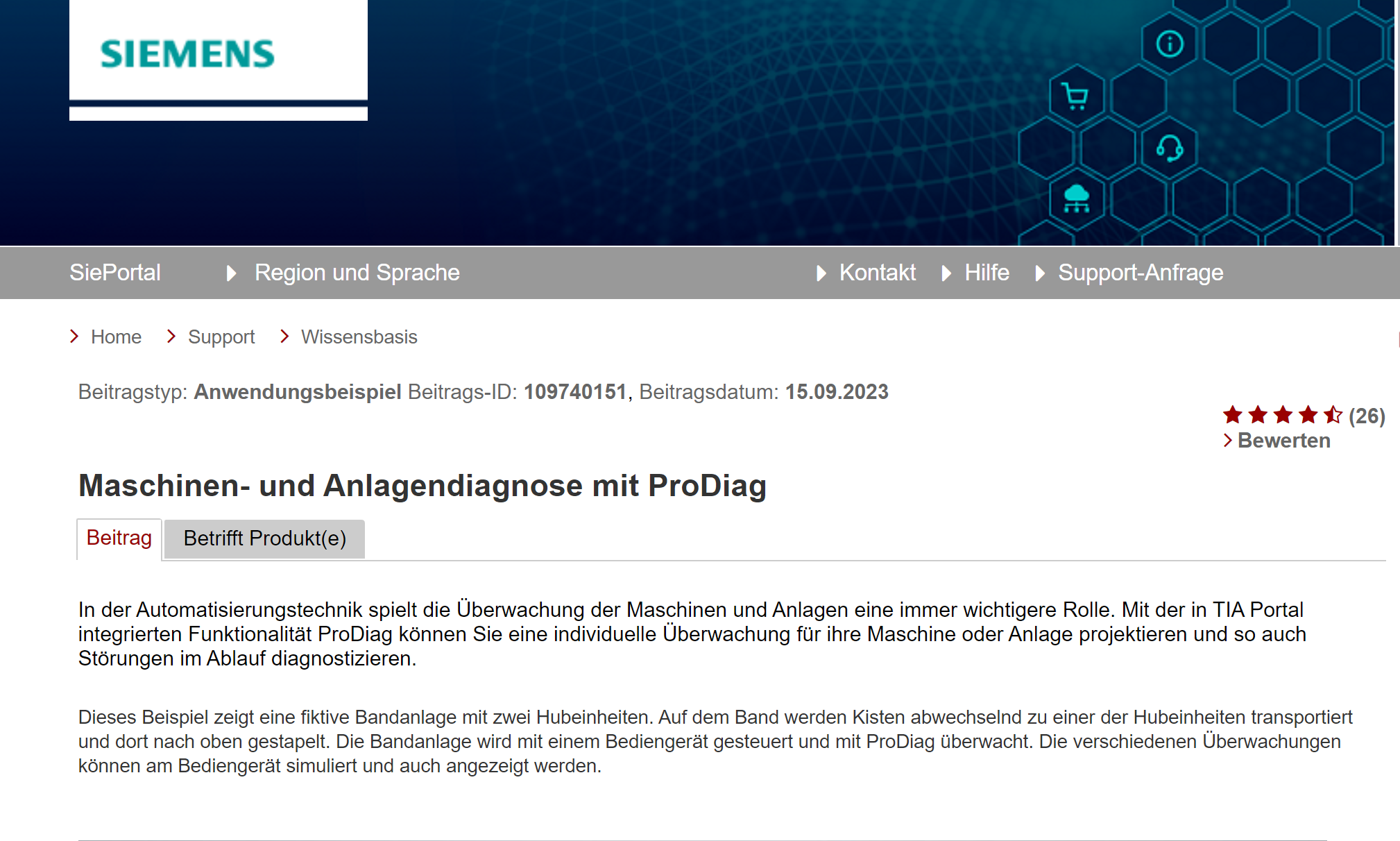

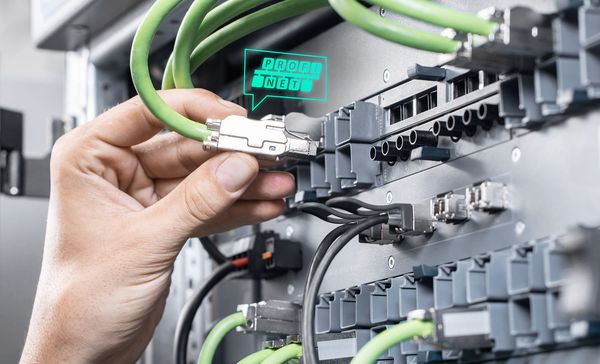

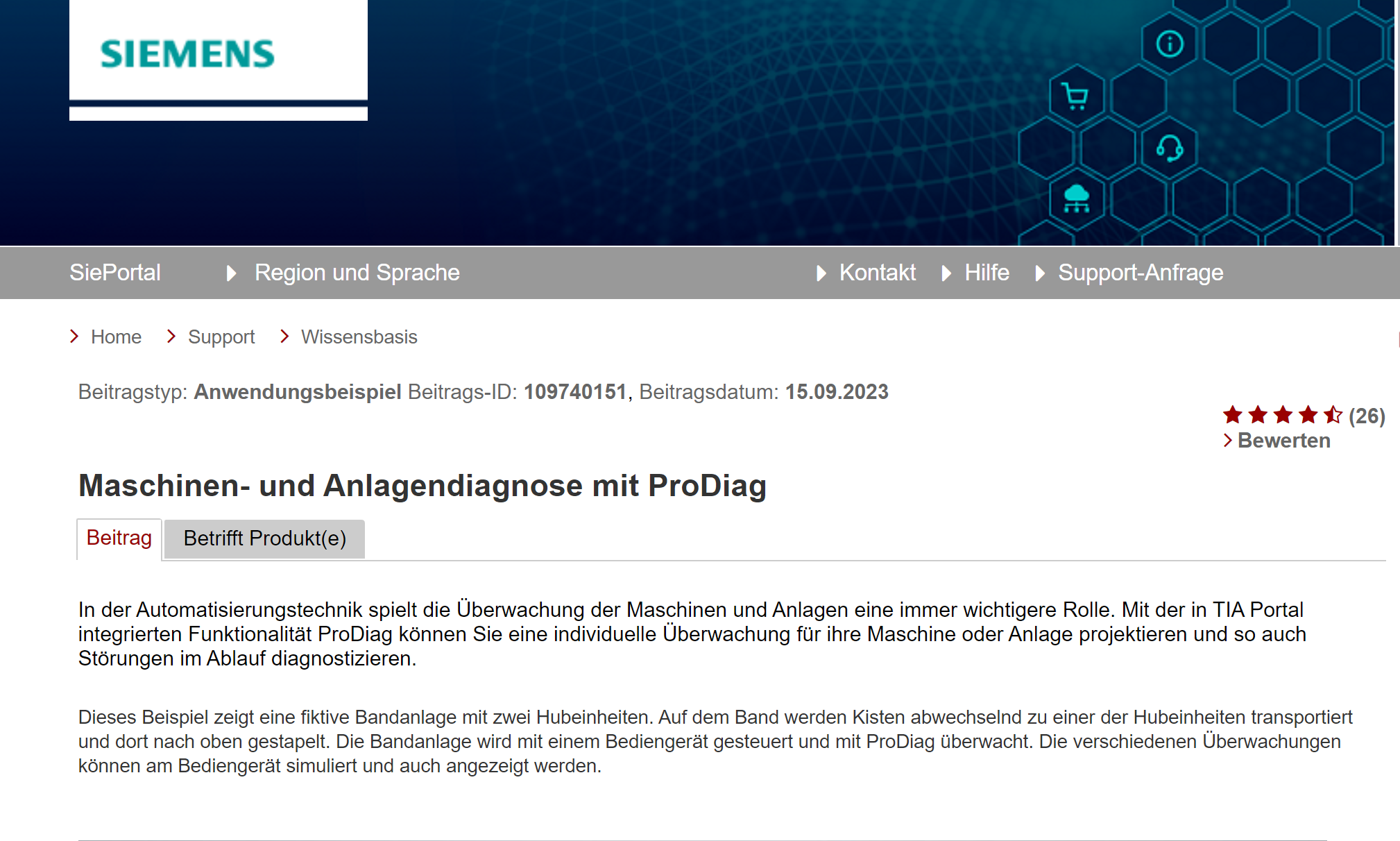

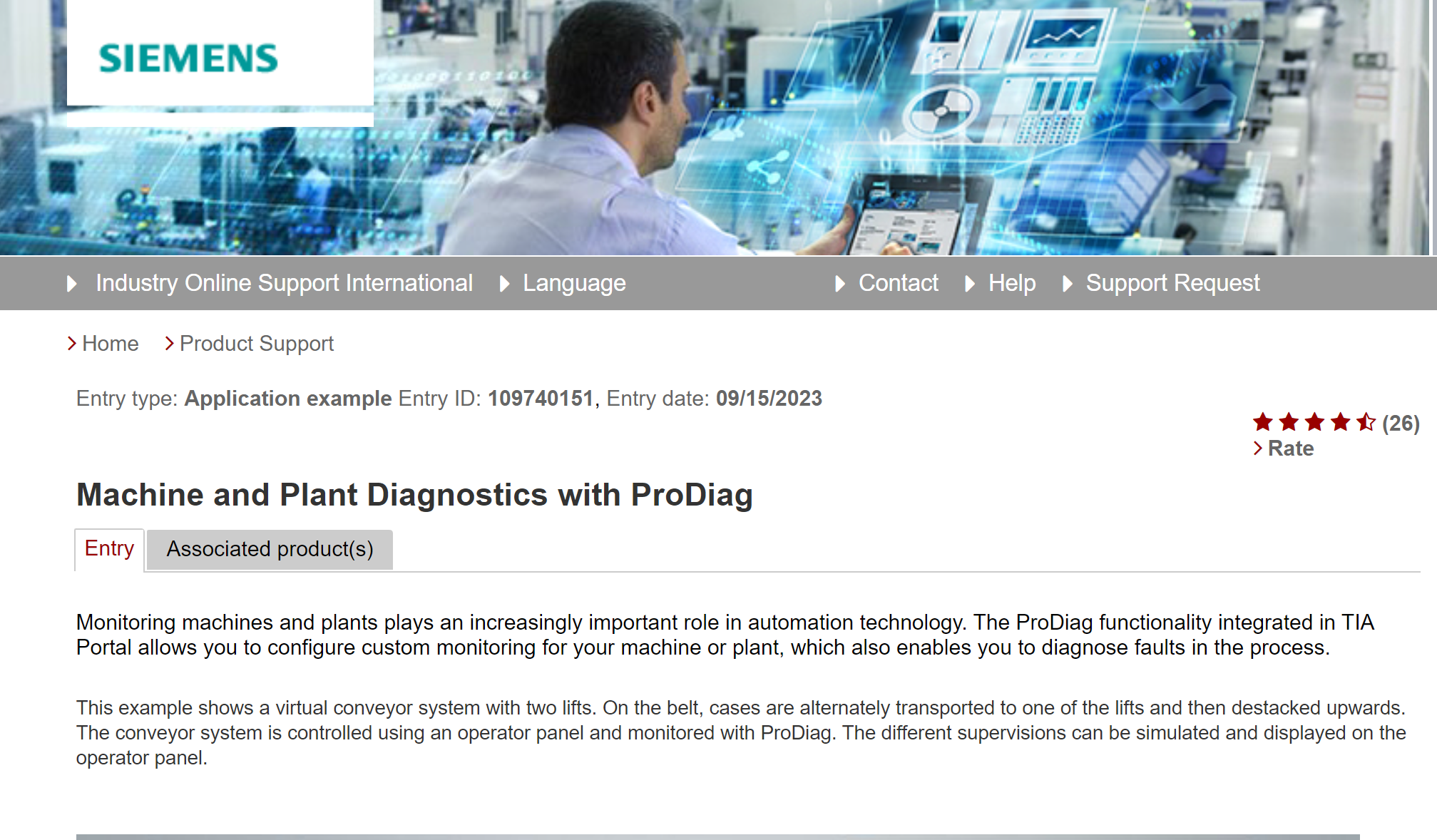

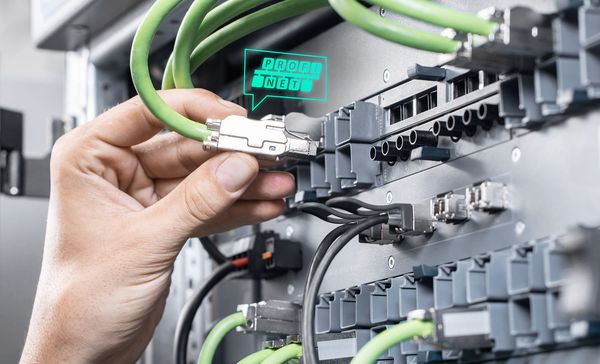

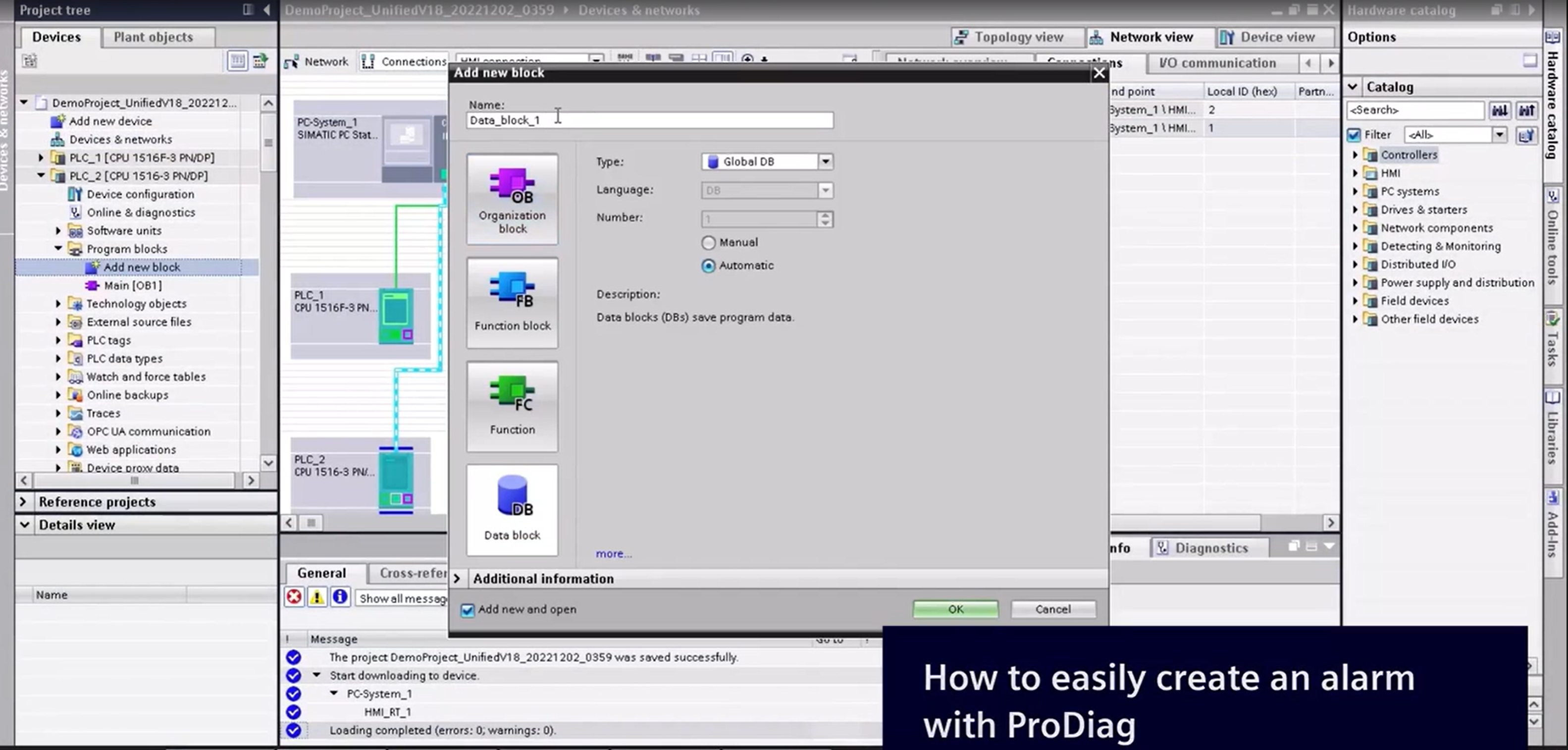

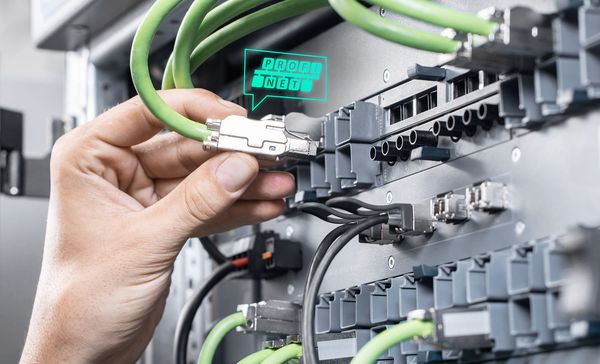

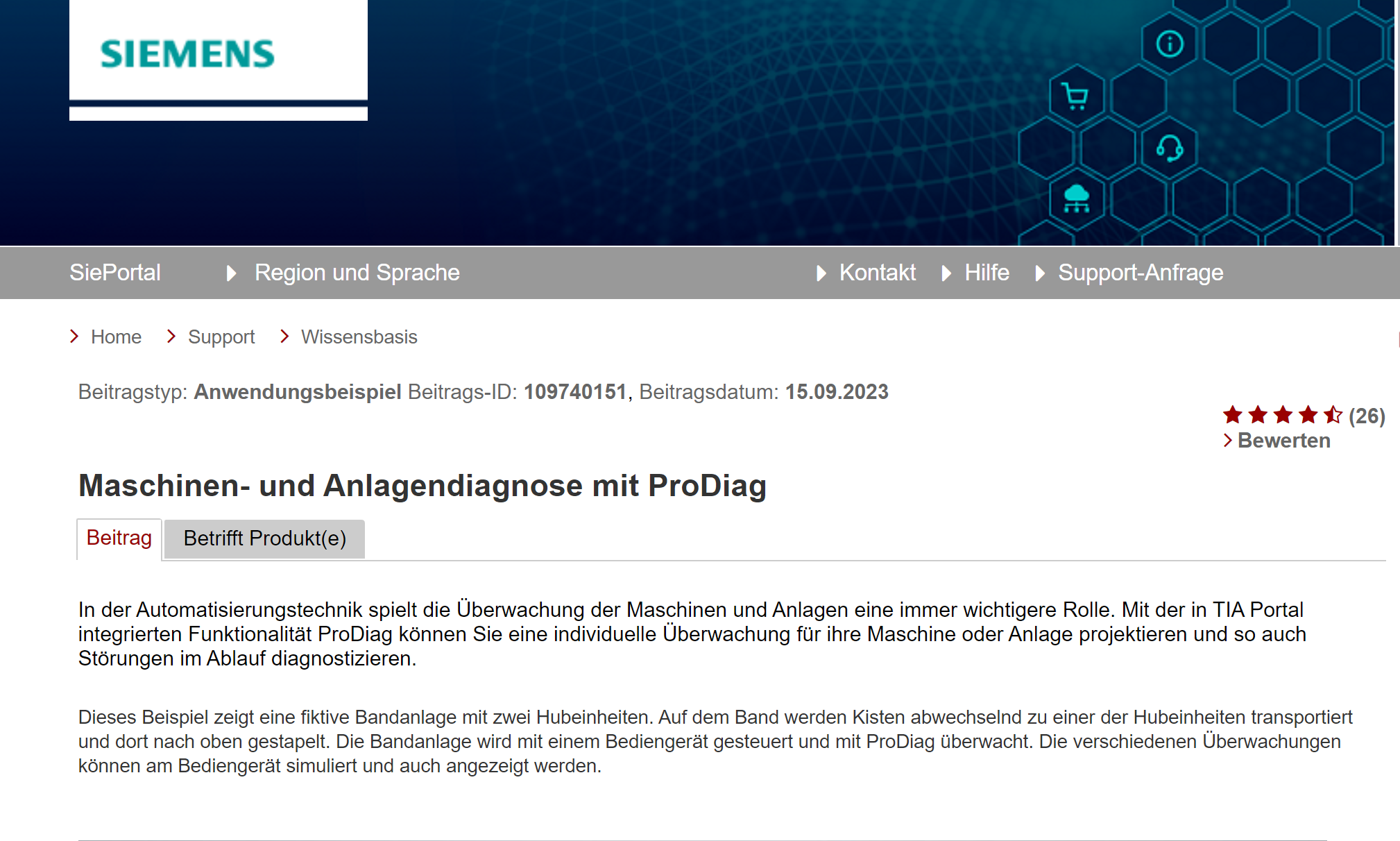

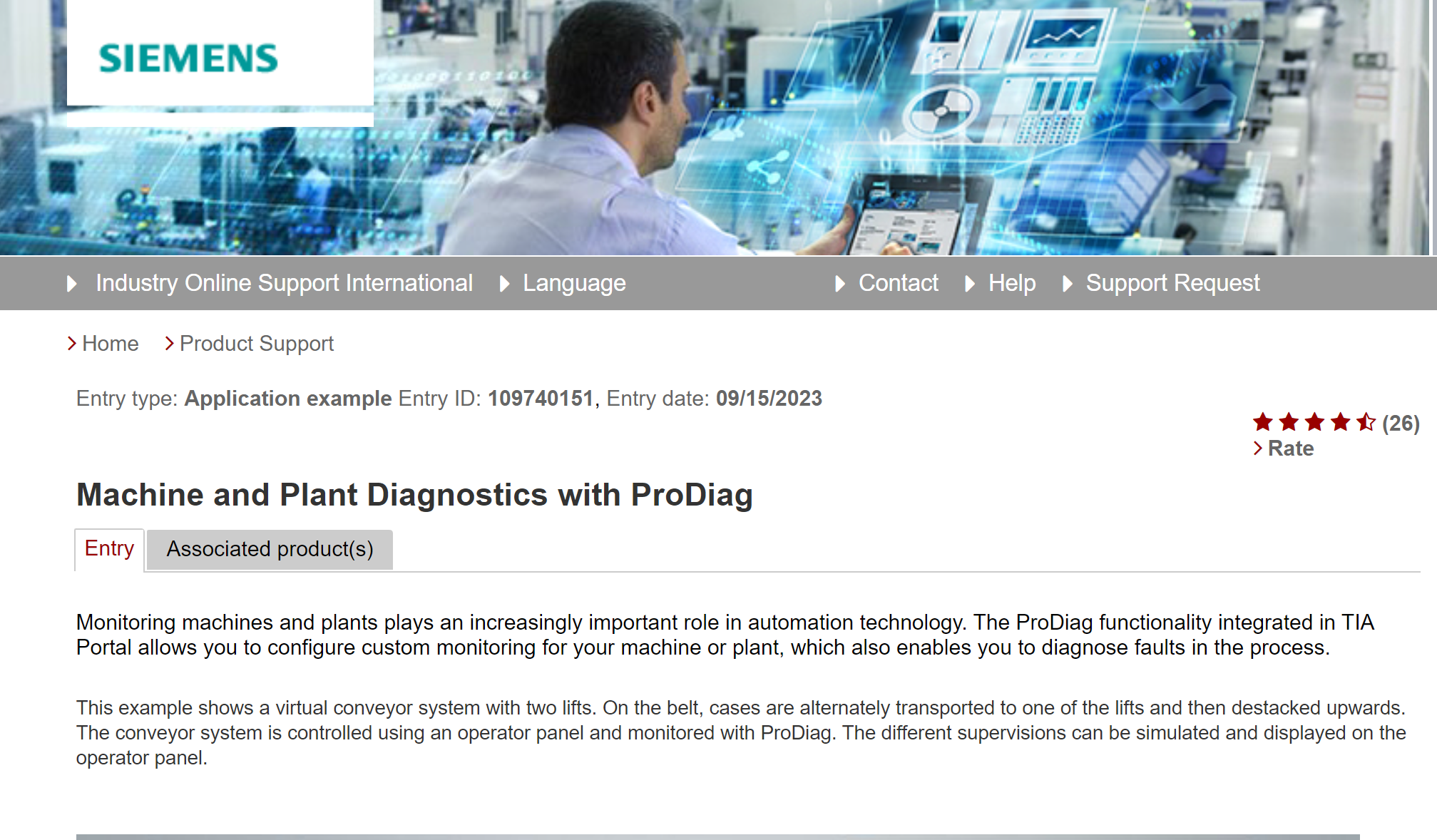

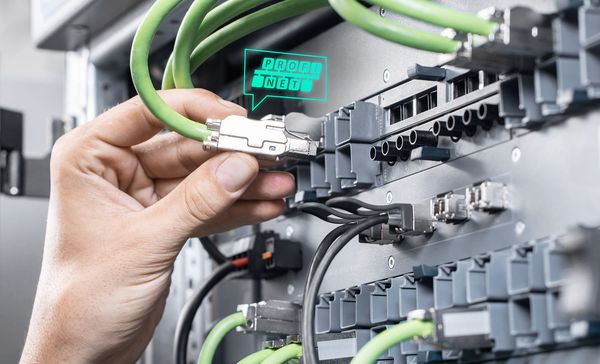

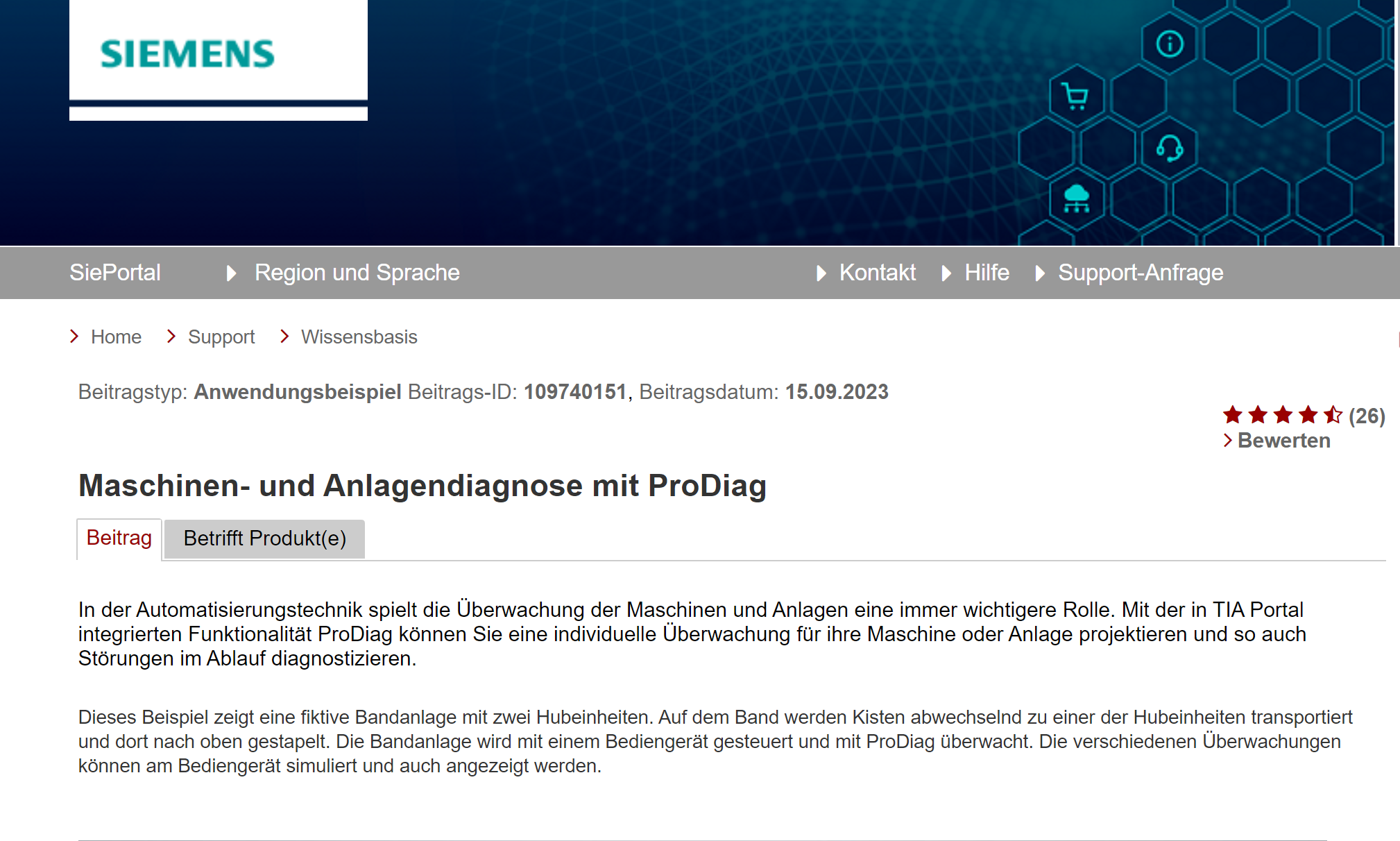

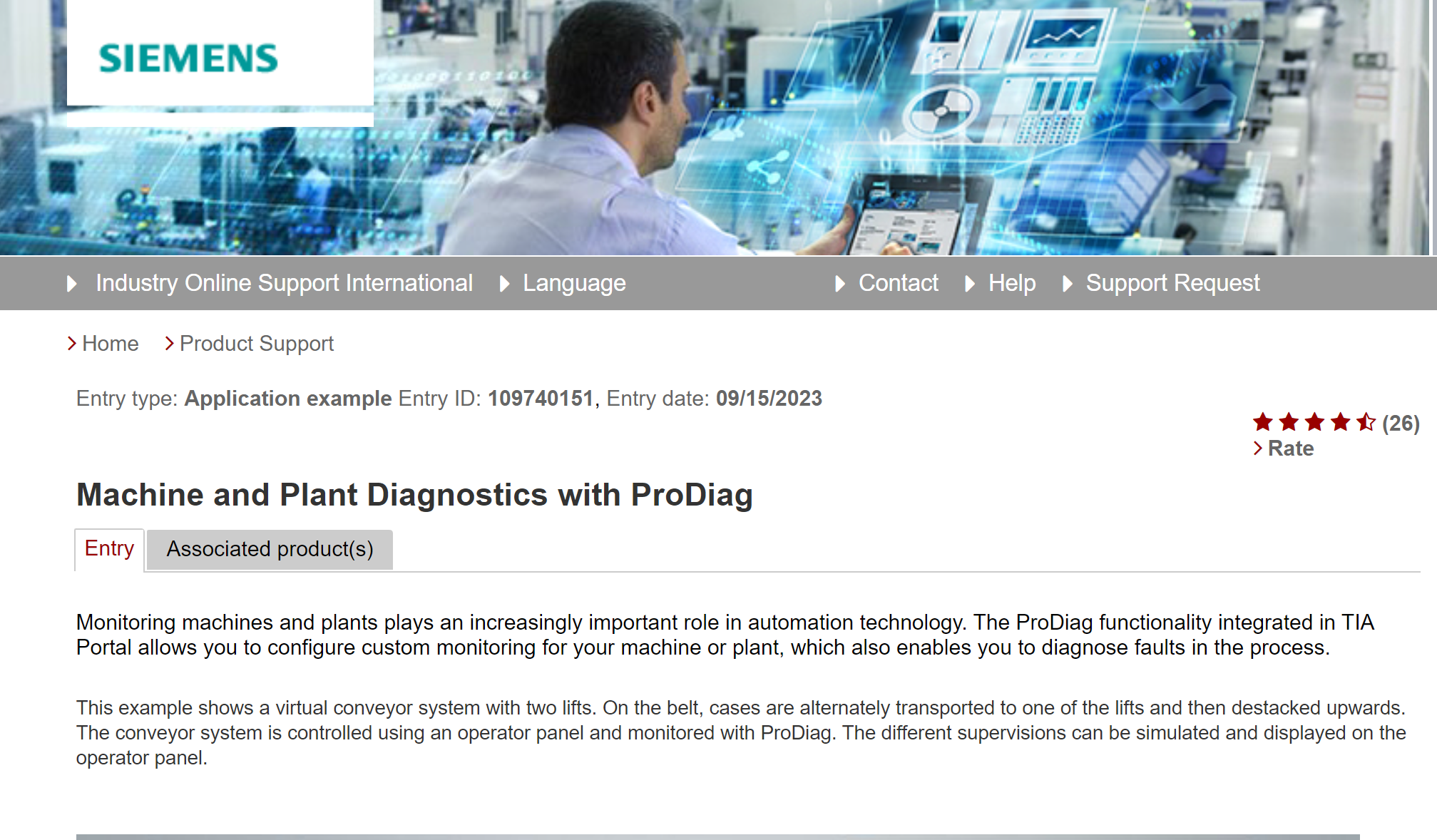

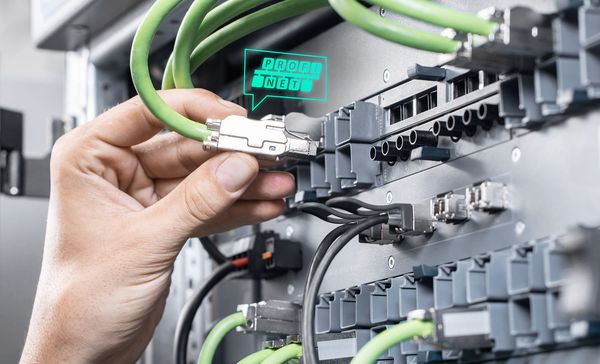

Standardized diagnostics of devices for increased plant availability

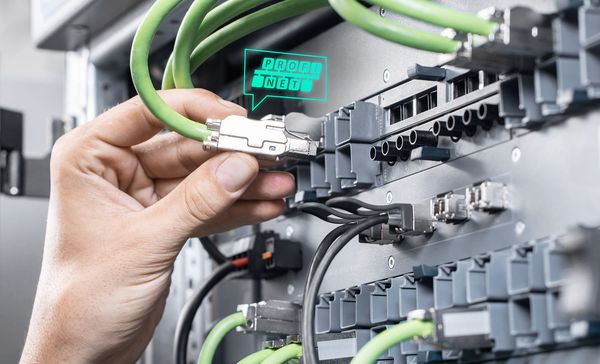

PROFINET and TIA Portal offer standardized diagnostic solutions for devices, enabling quick error detection and reduced downtime. By providing uniform and vendor-independent diagnostic messages, problems can be efficiently identified and resolved, thereby increasing plant availability.

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your direct link to our solutions

The following section provide you with the information you need to get started.

Your team section heading [24pt, SiemensSansProfRoman]

The subheading for your team section [16pt, SiemensSansProfRoman]

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

We'd love to hear from you

Whether you have a question about features, trials, pricing, need a demo, or anything else, our team is ready to answer all your questions