Standardized integration and modularity

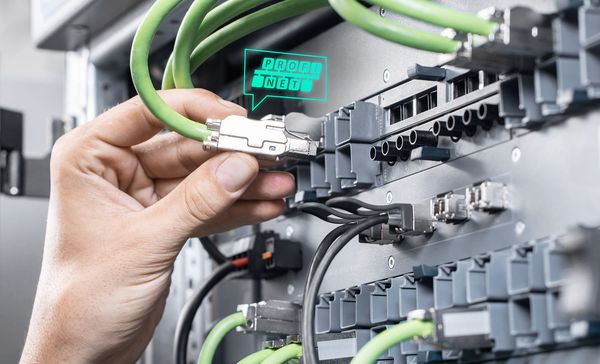

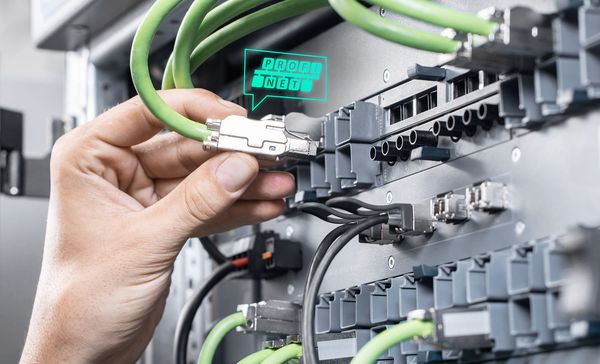

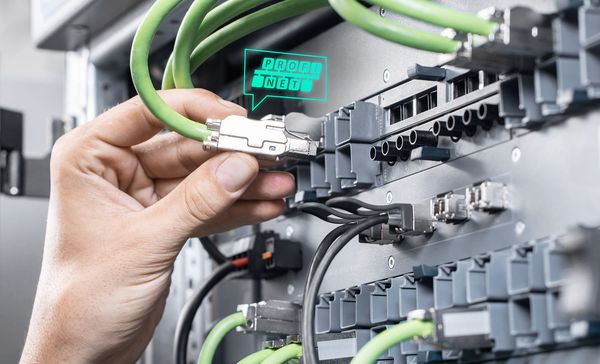

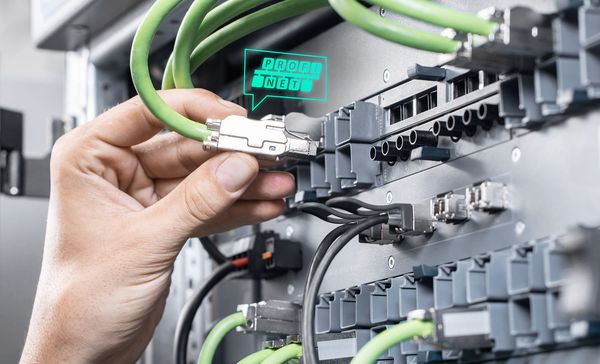

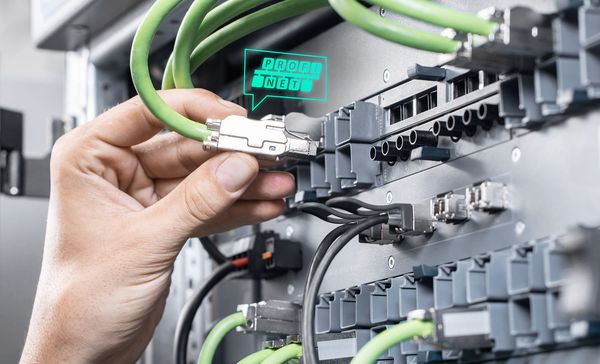

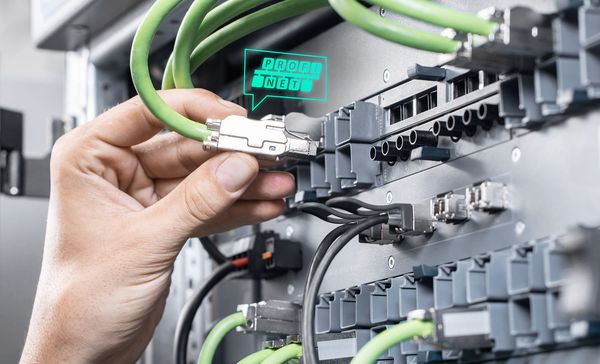

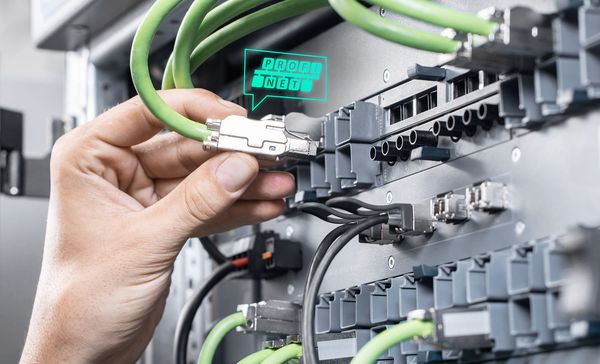

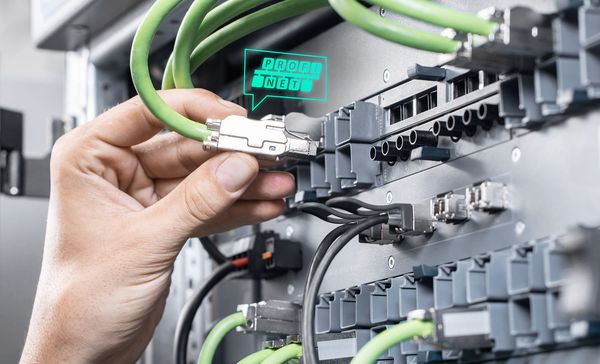

Without standardization, the integration of new machines into existing lines or the replacement of a machine results in costly adaptations. A consistent standardization approach for horizontal and vertical integration enables plug-and-produce based on standardized interfaces such as PROFINET, OPC UA or Companion Specifications. This allows you to produce earlier and save costs. A modular machine concept reduces complexity, error rate, and integration time.

Overall information

Get more insights to horizontal and vertical integration.

Line integration with OPC UA

OPC UA and its companion specifications enable fast and cost-effective line integration with high scalability, fault-free commissioning, and a fast factory acceptance test. Thanks to the internationally defined OPC UA companion specifications, you benefit from the line integration of standardized data interfaces and status models – allowing you, for example, to easily adapt machine interfaces and reuse modules for different plants.

Modular production with Module Type Package (MTP)

The basic structure of your plant is fixed. All other components or technical actors are building blocks. Depending on what you want to produce, modules are added or disconnected and put into operation. These modules can always rearrange and configure themselves - depending on the demand. And, all this without having to reprogram the processes or install drivers. The required data and information are always available. This principle is also called Plug & Produce.

Your topic 3 headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your topic headline [24pt, SiemensSansProfRoman]

Your topic descrption [16pt, Siemens SansProfRoman]

Your direct link to our solutions

The following section provide you with more information you need to get started.

Your team section heading [24pt, SiemensSansProfRoman]

The subheading for your team section [16pt, SiemensSansProfRoman]

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

Team member name

Team member title

Link to [#00ffb9] >>>

We'd love to hear from you

Whether you have a question about features, trials, pricing, need a demo, or anything else, our team is ready to answer all your questions